Posts

New Laminam tabletop finish

The new Laminam tabletops offer a material-like and sculptural aesthetic, complemented by exceptional technical performance. Available for both fixed and extendable tables, they are suitable for indoor and outdoor use. Thanks to the Made in Italy production technology, Laminam surfaces are safe, hygienic, and easy to maintain. They are scratch and abrasion resistant, and withstand weather agents and UV rays. All while fully respecting the environment and the territory: 94% of the materials used by Laminam are of natural origin. Each surface, depending on the type, contains 20–40% pre–consumer recycled materials.

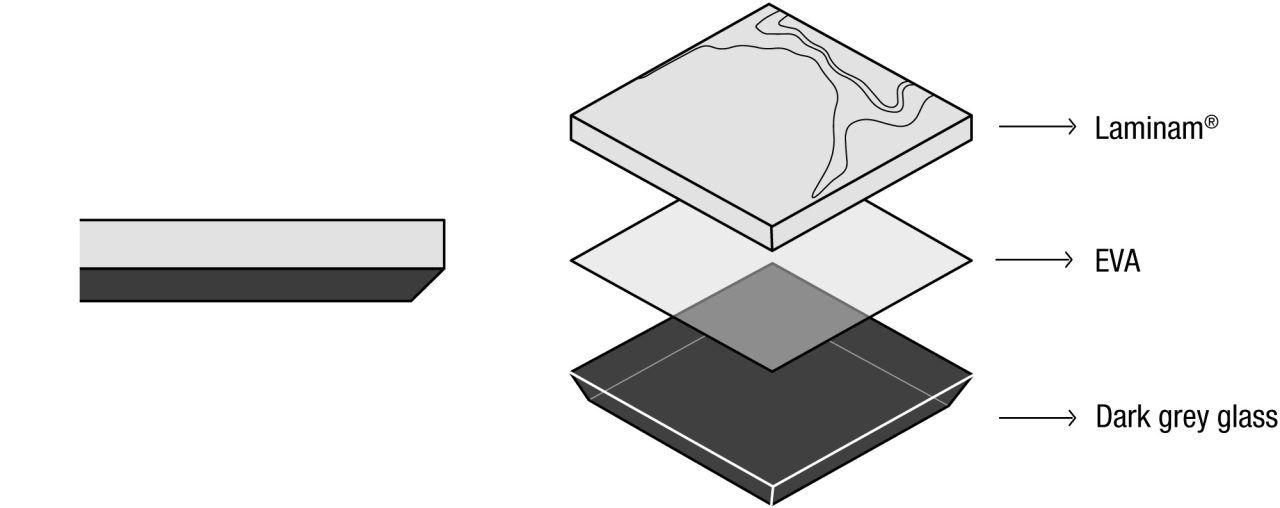

Laminam top stratification

All Kristalia’s Laminam tops are coupled with glass to ensure maximum mechanical resistance. A thin layer of dark gray glass is glued to the ceramic through a lamination process. This process employs an extremely thin layer of EVA (ethylene vinyl acetate) with which the two layers are vacuum-sealed in a special oven. The dark glass is then trimmed at a 45° angle to make it less visible, allowing the observer to appreciate only the thin 6mm ceramic layer. The result is an extremely durable product, certified for use not only in indoor but also outdoor spaces.

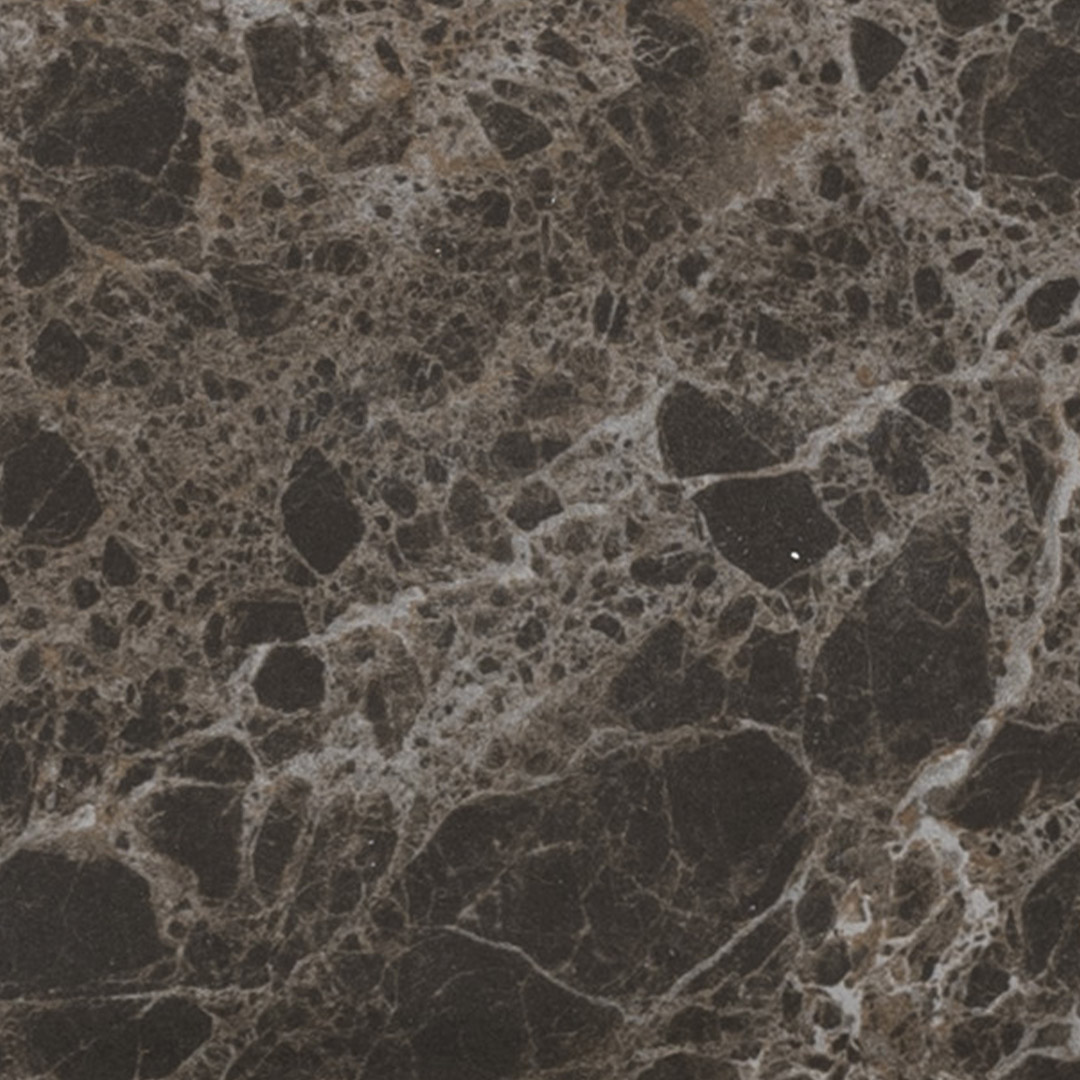

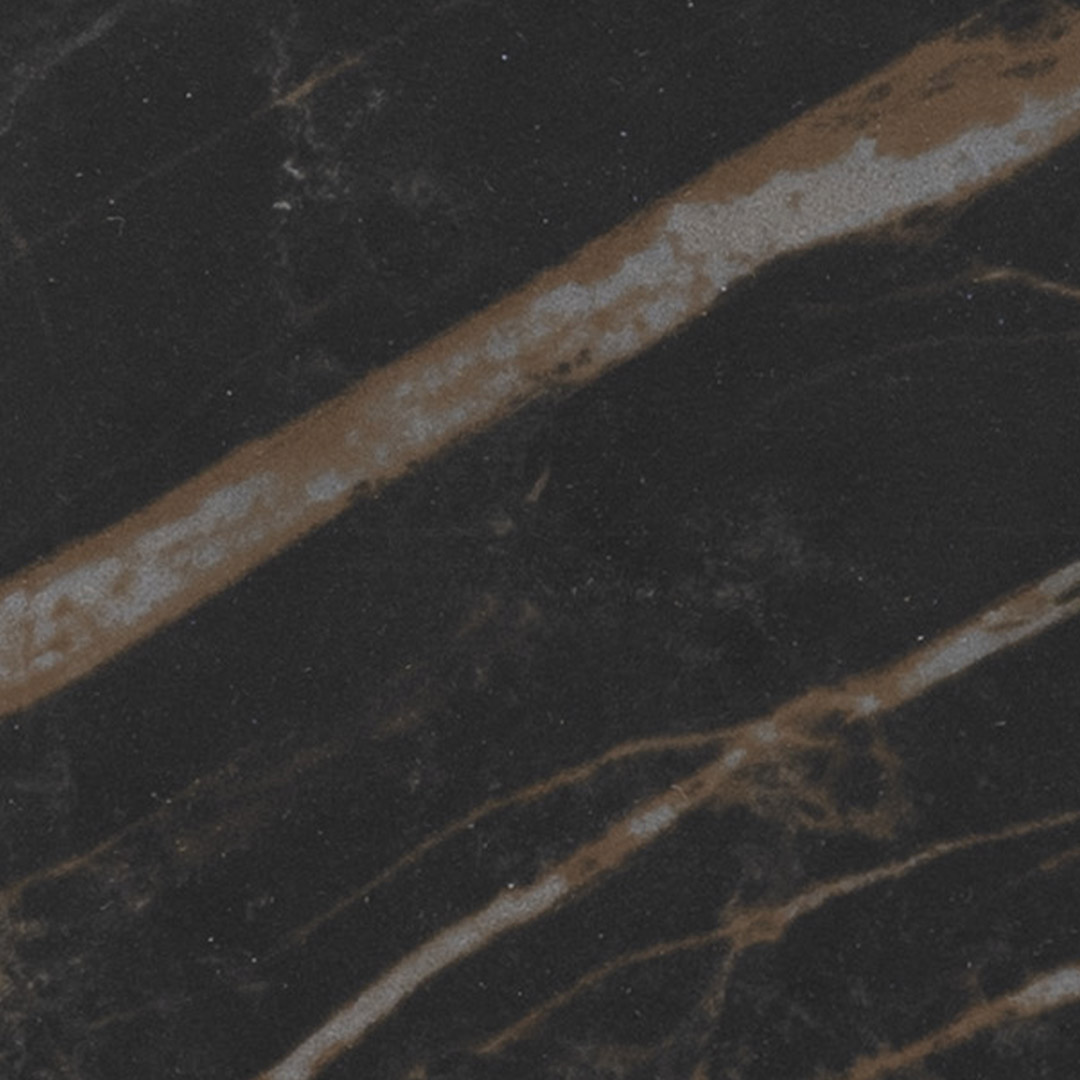

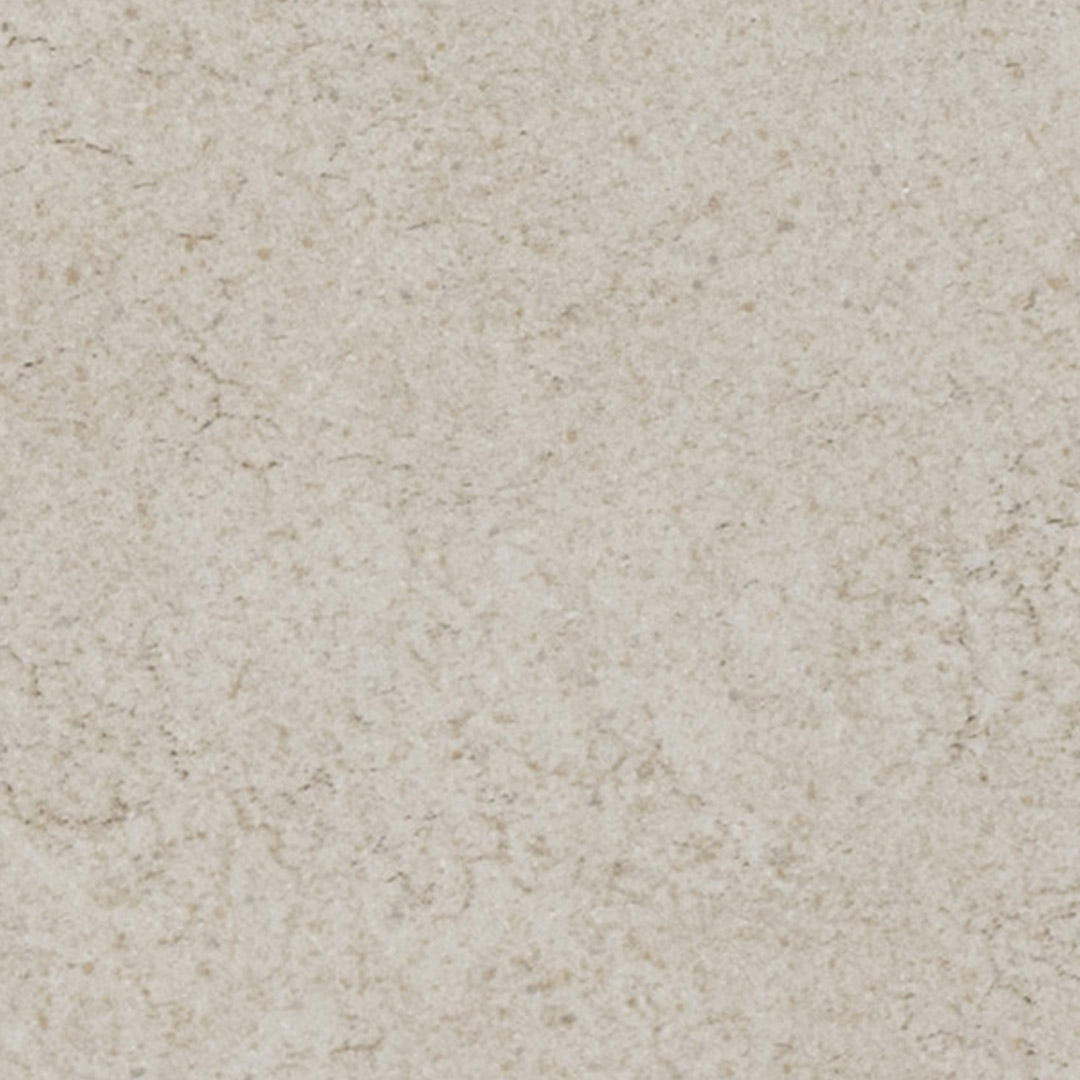

Colors

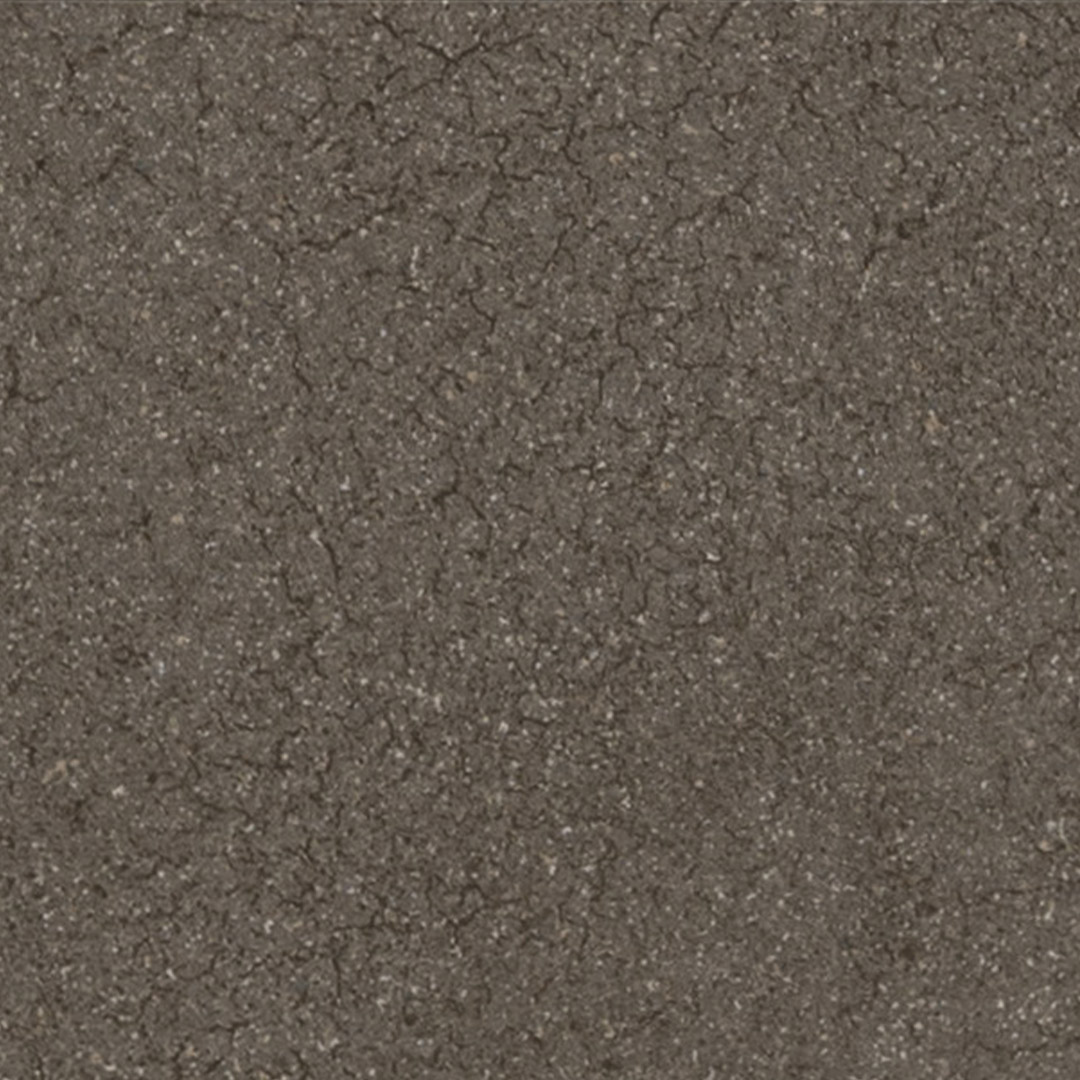

Pietra Piasentina Grigio

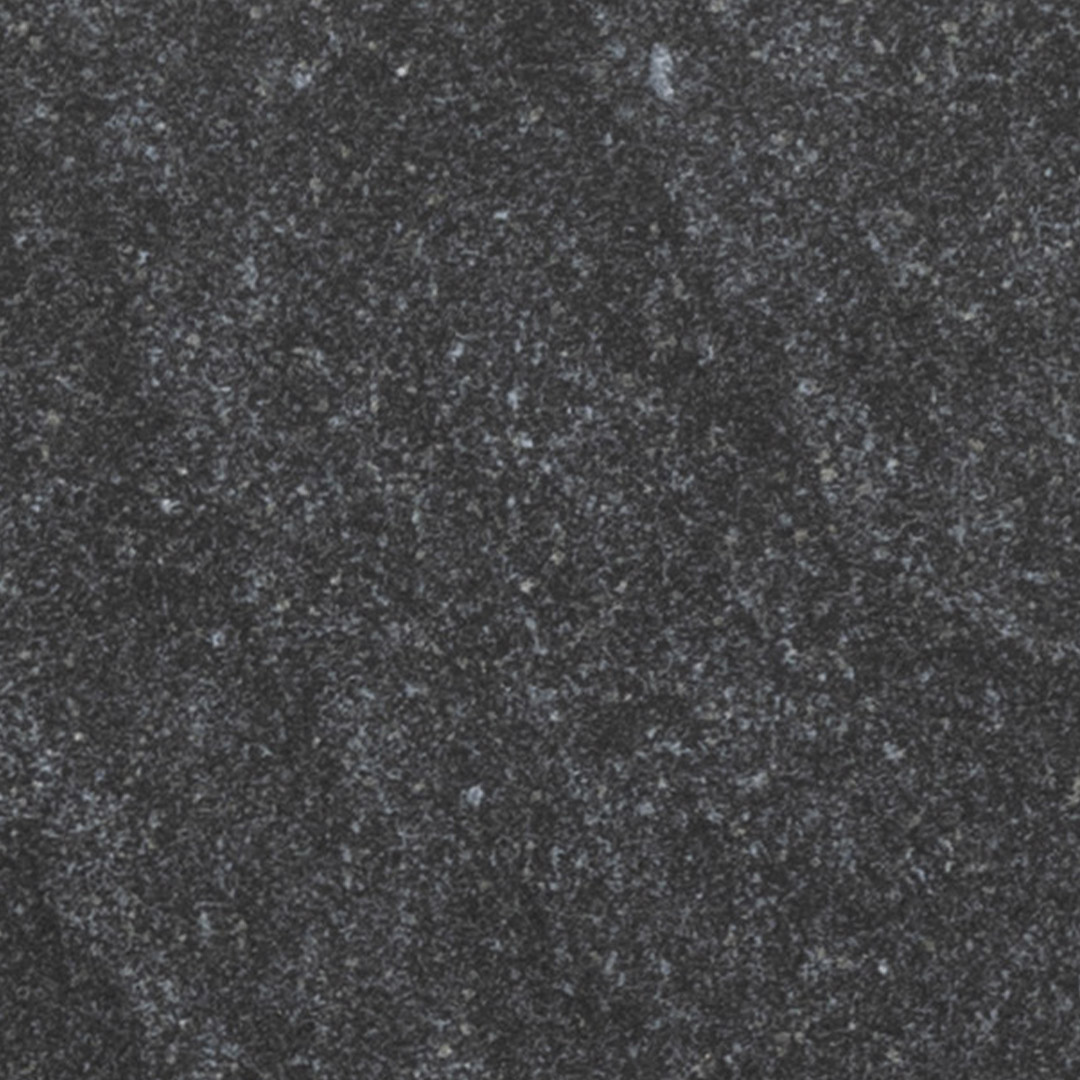

Pietra di Cardoso Nero

Tables with Laminam tabletops

Bottega

Kensaku Oshiro

Bodoni

Sam Hecht and Kim Colin

Sushi

Bartoli Design

Cleaning and maintenance

For the regular cleaning of Laminam ceramic surfaces, simply use a microfiber cloth dampened with water and neutral detergent. Wipe the cloth over the surface, rinse with water, and dry carefully.

In case of stubborn residue, it is advisable to perform a thorough cleaning using professional products following the procedures outlined on the “Cleaning and Maintenance” page of the Laminam website.